Plant & Machinery

- Electric Furnace -20MT Capacity.

- Ladle Refining Furnace.

- Vacuum Degassing

- Cored Wire Feeding System

- Continuous Casting Machine of 10.25/19 & 6/11 Meter radius .

- Electro Magnetic stirrer.

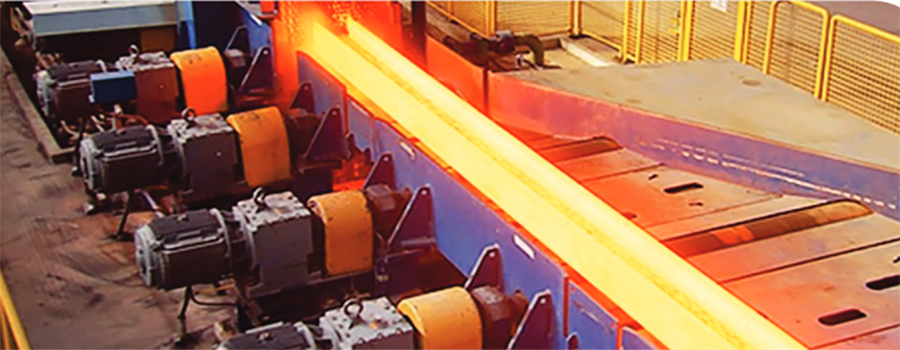

- 3 High, 24” Rolling Mill.

- 3 High, 18” Rolling Mill.

- 3High 10” Rolling Mill

- Reheating furnace - Pusher type.

- Descaler.

- Heat treatment furnace with 30mt capacity

- Roller Straightening Machines 2nos.

- Press type straightening Machine

- Draw Bench for cold drawing

- Peeled & Ground bars production facility.

- Oxygen Plant 170Cubic Meter Capacity

- Forging Ingot Casting Facility

- Casting of Rolls, Rings, Fly Wheels, Pinions, Gears

- Heavy Rounds Hot Forging Facility

Testing Equipments

- O.E Spectrometer.

- Mobile Spectrometer.

- Metallurgical Microscope with image Analyzer.

- Rock well Hardness Tester.

- Brinell Hardness Tester.

- Universal Testing Machine.

- Impact Testing Machine.

- Jominy Quenching Apparatus.

- Radioactive Element Check Meter

- Ultrasonic Flaw Detector.

- Magnetic Particle Inspection.

- Upset Test Press.

Product Supply Conditions

- Hot Rolled Black Bars

- Hot Forged Bars

- Hot Forged & Turned/Machined Bars.

- Bright Bar in Cold Drawn, Peeled & Polish

supply condition in h11 /h9 tolerances. - Heat Treatment Condition: Annealing,

Spherodising Annealing, ISO-Annealing,

Normalizing & Tempring.

- Hardened & Tempered in specified

Conditions like S', 'T', 'U', 'V' & 'W'.

- Special Profiles : As per order